Process training and operational training have been a core service for PTS since the day that we were founded. The success of the projects that we design and manage depends on an effective transfer of operational expertise to our customers. PTS of course helps to coordinate vendor training in equipment operation and maintenance. However, most customers need much more than vendor training to achieve an efficient and sustainable manufacturing operation.

PTS training programs are all focused on the operational side of the clients’ business. We invest considerable effort in our electrical and piping drawings to provide a consistent and individual device tagging system. PTS then requires contractors to install all measurement and control devices with matching physical identification. That design structure is then incorporated into the process control log sheets and/or software that we provide as part of our standard scope. The process tracking system becomes the basis for the entire system of PTS operational guidelines and the associated operational training programs.

The basic objective of all PTS training programs is to teach the client how to effectively operate the manufacturing operation on a day to day basis. We focus on developing and practicing a complete system of operational guidelines that lead to effective troubleshooting and Predictive Maintenance. We realize that plant staff will not at first retain all of the theory that is taught in class. The first step in achieving a successful operation during the inevitable learning curve is therefore the transfer and implementation of a comprehensive set of operating procedures.

PTS is widely regarded in the beverage industry as having one of the most effective training programs in plastic container processing. Our training programs in PET Processing, Statistical Process Control/Six Sigma, Design of Experiment and Utility Systems Design are utilized in North America, South America and Asia by all of the major multinational beverage companies and many of the major plastics converters.

Course Offerings:

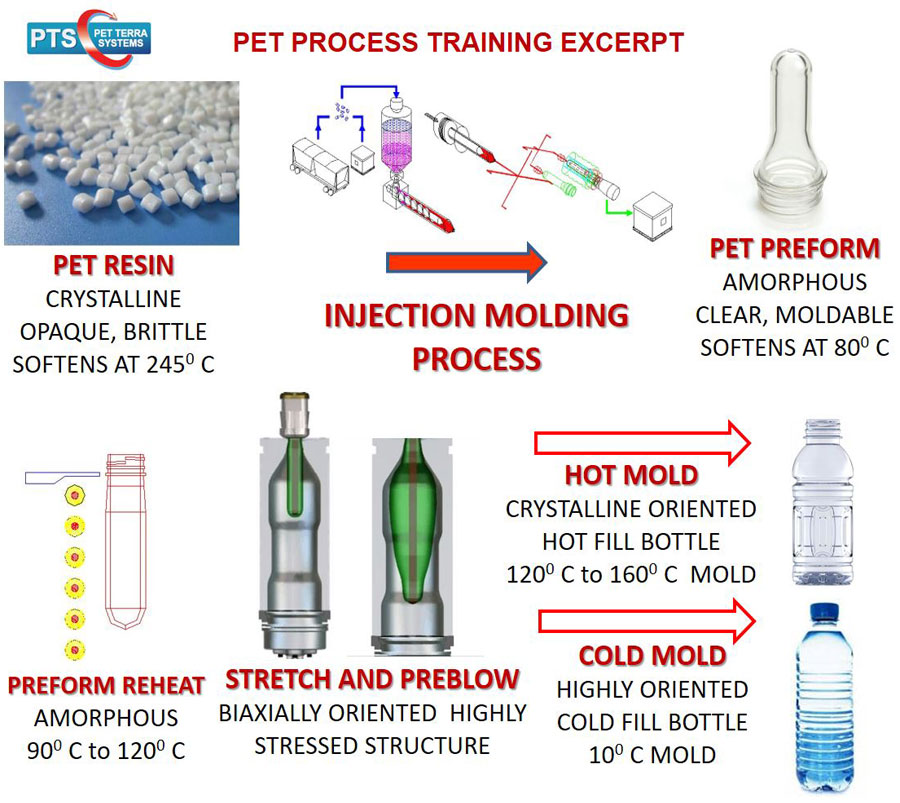

- PET 101 – Blow Molding Process Theory and Process Optimization

- Injection and Blow Molding Process Theory and Application

- Design of Experiment – Statistical Modeling of All Processes (filling, labeling, packaging, closure manufacturing, extrusion molding, injection molding, reheat blow molding, etc).

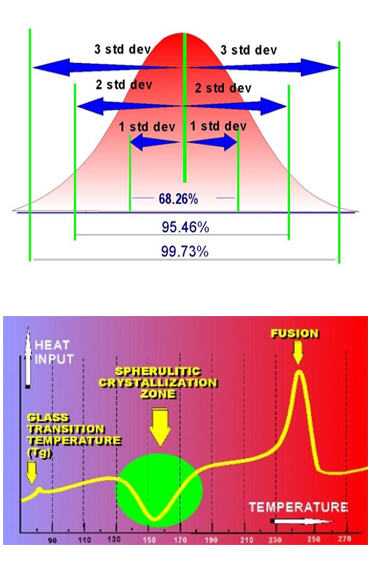

- Statistical Process Control – SPC Theory, SPC Application, SPC Programming, etc.

- Comprehensive Six Sigma Certification Program

- Utility Systems Design – Compressed Air Systems, Cooling Systems, Refrigeration and HVAC Systems, Material Handling Systems